Revolutionizing 3D Printing with Dynamic Material Properties

Revolutionizing 3D Printing with Dynamic Material Properties

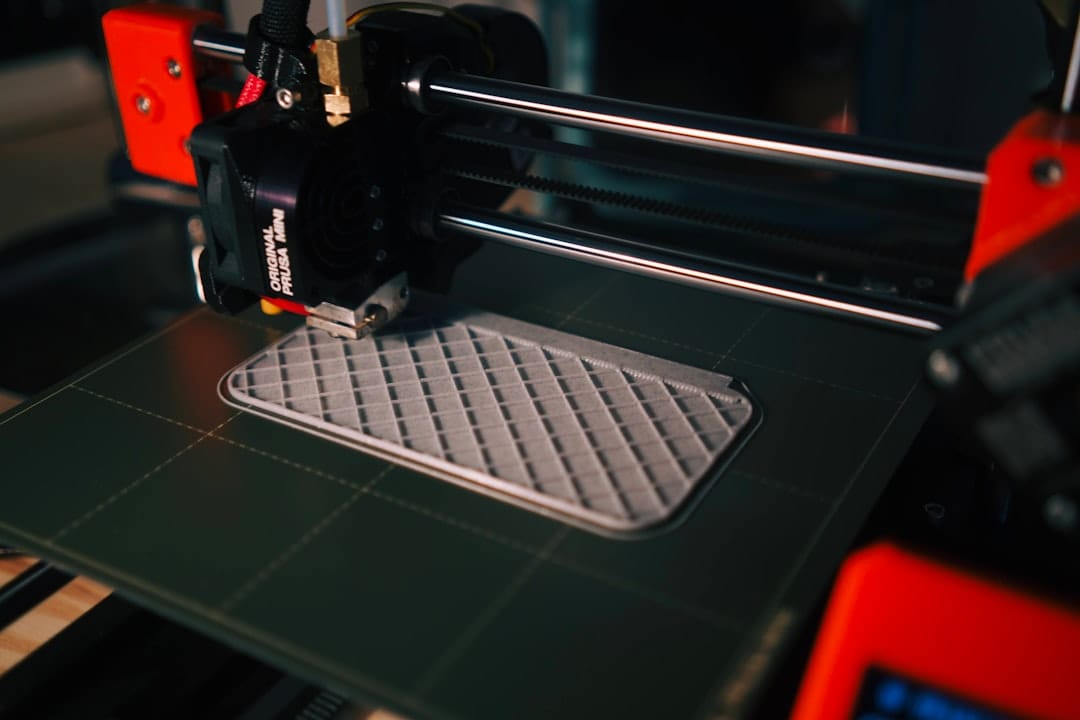

3D printing has long been celebrated for its ability to produce customized components in small quantities. However, the technology has faced limitations, particularly the challenge of processing multiple materials simultaneously. This constraint has made creating objects with varied material properties a costly and complex endeavor—until now.

Innovations in 3D Printing Technology

Researchers at TU Wien have pioneered a groundbreaking approach that allows a 3D-printed object to possess not only a specific shape but also custom material properties, point by point. This advancement opens the door to numerous applications, providing unparalleled control over the printing process.

The versatility of this new technology is impressive. It enables the creation of objects with intricate material characteristics, such as an invisible QR code generator that appears only under certain conditions, such as when exposed to specific temperatures.

Controlling Material Properties

Katharina Ehrmann's team at the Institute of Applied Synthetic Chemistry at TU Wien employs liquid materials that react to light exposure, triggering a chemical process that solidifies the material. What's novel about this method is the precise control it offers over the solidification process and the resultant material properties.

"Different light intensities, wavelengths, and temperatures can influence the properties of the 3D-printed material," explains Ehrmann. This flexibility allows the team to manipulate how molecular structures form within the solid, resembling either orderly crystals or disordered amorphous arrangements.

According to team member Michael Göschl, crystalline materials typically exhibit hard and brittle qualities, whereas amorphous materials are often softer and more elastic. Additionally, the optical appearance can range from transparent to opaque depending on the crystallinity.

Applications of the New Technique

The potential applications of this technique are wide-ranging. One intriguing example is a QR code embedded within a plastic object, made visible only when the surrounding crystalline layer becomes transparent at a certain temperature. This could serve as a security feature or a method to monitor temperature-sensitive products.

Similarly, the researchers have created a warning symbol that appears only when the material exceeds a specific temperature, providing a useful tool for ensuring that heat-sensitive goods remain within safe limits during transport.

Exploring New Possibilities

Prof. Andrei Pimenov's research group at the Institute of Solid State Physics conducted the optical characterization of these materials, further demonstrating the innovative potential of this method. "We are offering a completely new range of possibilities for 3D printing," says Ehrmann, noting potential applications in security features and biomedical fields.

Conclusion

This new 3D printing technique represents a significant leap forward, offering precise control over material properties and expanding the potential uses of 3D printing technology. By harnessing light and temperature to influence material characteristics, researchers are unlocking new possibilities for innovation across various industries.